- 22 Jul 2024

- 2 Minutes to read

When to use FLACS vs EFFECTS

- Updated on 22 Jul 2024

- 2 Minutes to read

Gexcon's X-Suite comprises three advanced software tools — FLACS, EFFECTS, and RISKCURVES — out of which FLACS and EFFECTS are designed to address various aspects of consequence analysis. These tools serve distinct purposes based on their underlying modelling approaches — CFD modelling for FLACS and integral modelling for EFFECTS. Understanding the differences between these consequence modelling methods and knowing when to use each tool is crucial for accurate and efficient hazard analysis.

Integral vs. CFD Modelling

Integral modelling with EFFECTS

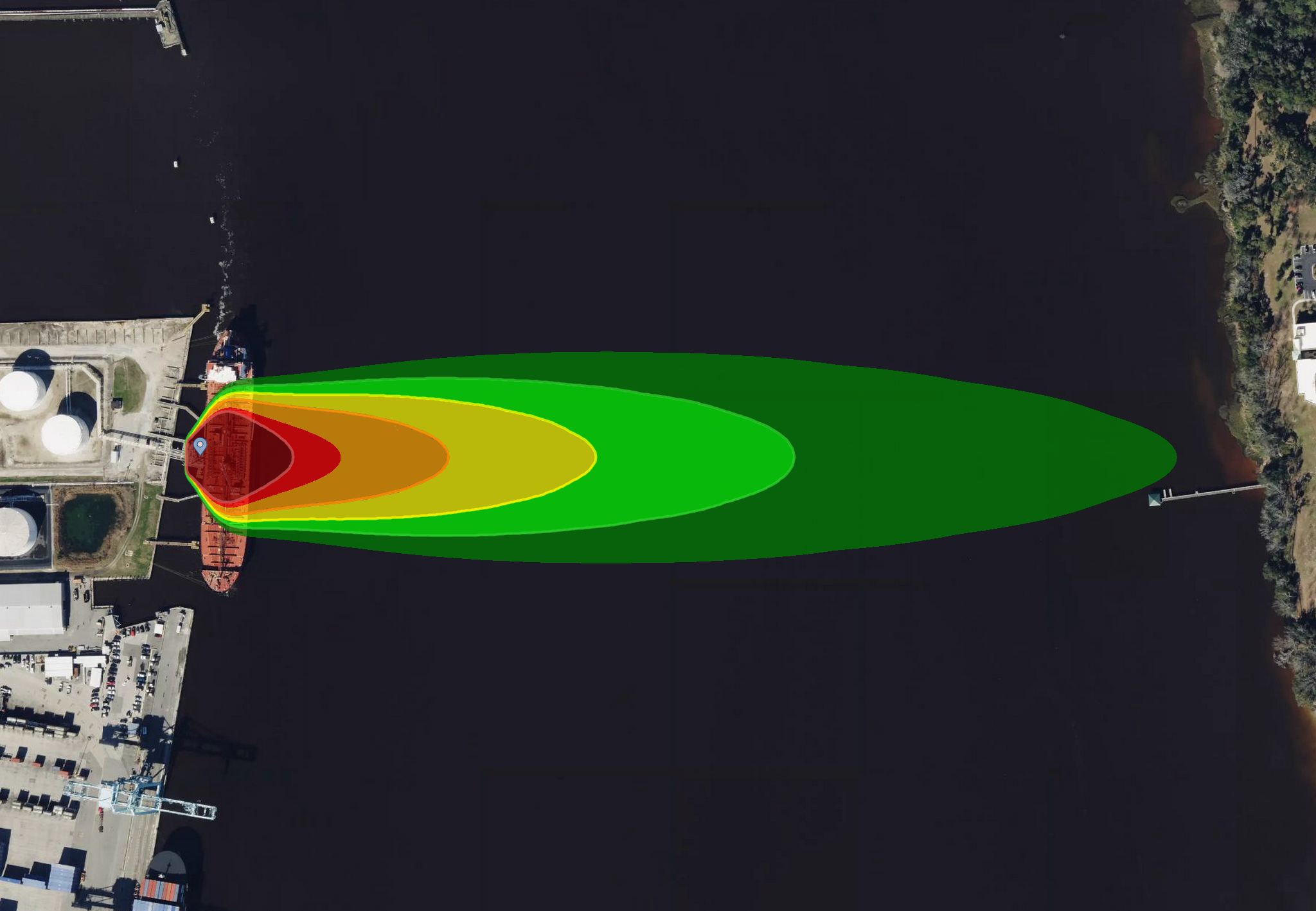

Integral modelling, as implemented in the EFFECTS tool, relies on analytical and empirical relationships to deliver quick and broad estimations of hazard consequences. This method is particularly advantageous in scenarios where obstacles can be considered as integral roughness and where rapid computations are necessary.

CFD modelling with FLACS

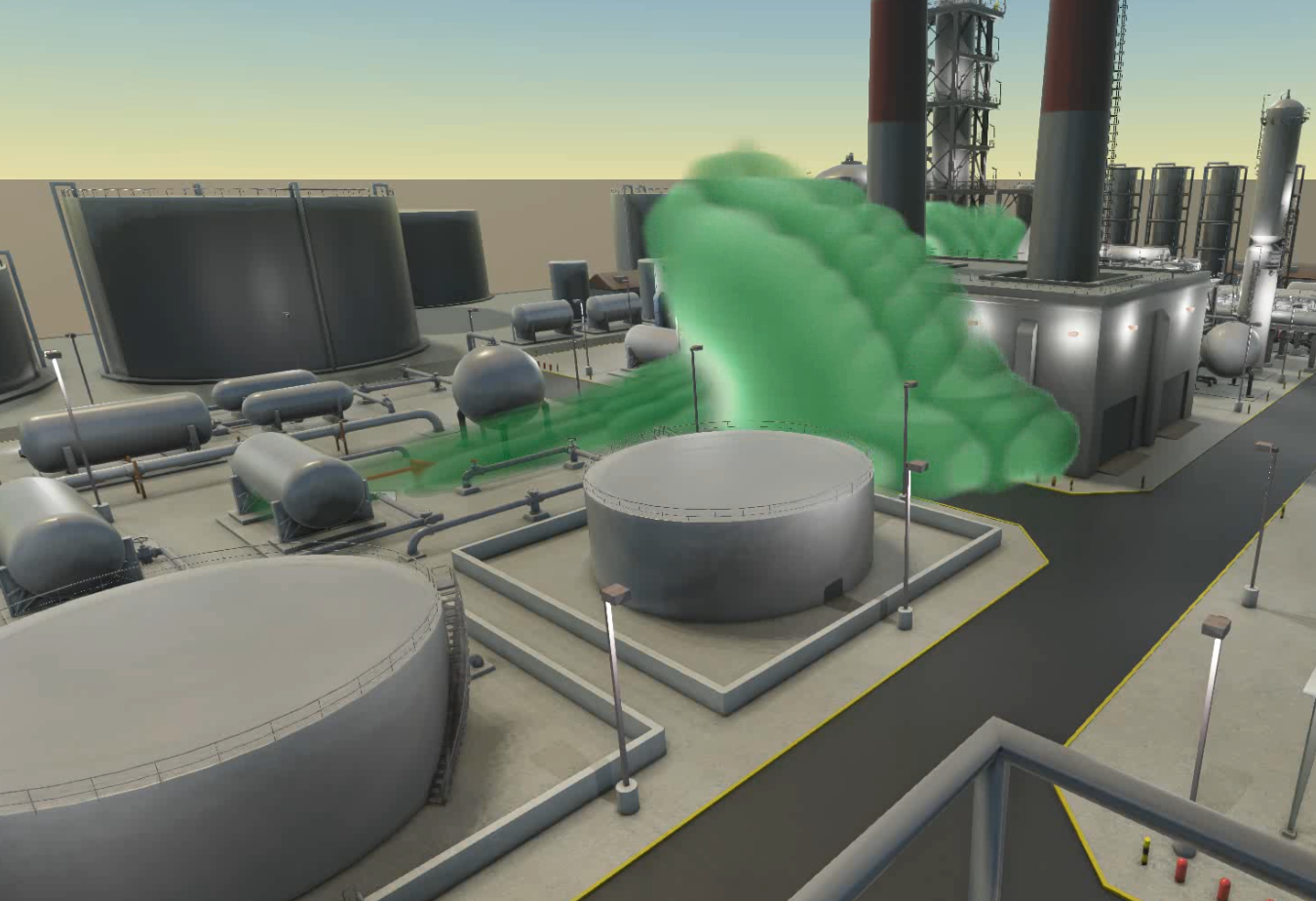

In contrast, FLACS applies Computational Fluid Dynamics (CFD) modelling, a sophisticated numerical approach that simulates the behaviour of fluids and gases. CFD divides the area of interest into a grid of small cells and solves equations for mass, momentum, and energy conservation in each cell. This method enables FLACS to predict fluid flow, heat transfer, and chemical reactions within complex 3D geometries. The CFD approach is particularly crucial when the spatial arrangement of obstacles significantly affects the flow, such as in confined spaces or areas where building structures influence dispersion patterns. By accounting for these intricate spatial relationships, CFD provides accurate predictions of gas dispersion and potential hazard zones in complex environments.

When to use EFFECTS

Rapid assessments: EFFECTS excels at quick calculations, allowing for the analysis of various releases and weather conditions in a short time.

Situations without complex geometries: Use EFFECTS when the scenario lacks complex geometries, and obstacles can be treated as integral roughness.

Screening tool: EFFECTS is effective as a preliminary screening tool to identify potentially hazardous scenarios before conducting more detailed analyses.

Example

Consider a scenario where a gas is released in an industrial park with mostly open areas and few structures. EFFECTS can swiftly model the dispersion since the area does not present complex geometrical constraints, enabling quick and accurate initial impact assessments without detailed 3D geometry.

When to use FLACS

Detailed analysis in complex geometries: FLACS is indispensable when the spatial configuration of obstacles, such as buildings or machinery, significantly impacts the flow.

3D visualisation: Use FLACS for detailed 3D visualisations that encompass the effects of real geometries and mitigation measures.

Specific location analysis: FLACS is preferable for analysing specific locations within or around structures where obstacles dominate the flow.

Example

In an industrial plant with a complex layout of piping and equipment, FLACS can accurately model dispersion patterns and interactions, providing precise predictions of hazardous areas.

Combining EFFECTS, FLACS, and RISKCURVES

Hybrid approach

By integrating EFFECTS and FLACS, users can leverage a hybrid calculation method that capitalises on the strengths of both tools. EFFECTS can be used for initial screening and rapid assessment of various scenarios, while FLACS can offer detailed analyses of specific locations where obstacles are significant.