- 10 Nov 2025

- 9 Minutes to read

MERGE validation case

- Updated on 10 Nov 2025

- 9 Minutes to read

MERGE (Modelling and experimental research into gas explosions) was a European‐funded research programme conducted from 1991 to 1993 which focused on obtaining a better understanding of vapour cloud explosions and how to model them. The objective was to provide a consistent set of data to validate predictive techniques and to improve phenomenological models to predict the effects of explosions.

The work consisted of three main parts:

Generation of experimental data concerning the effect of obstructed regions on flame propagation.

Large, medium and small scale experiments undertaken with different fuels comparing a wide range of venting with obstacles of different blockage. Blast pressure and flame speed was monitored.

Generation of experimental data to quantify the effect on flame propagation of the turbulence generated by a jet release.

The work was coordinated in the Netherlands by TNO and included contributions from British Gas, Christian Michelsen Institute, Imperial College, Telemark Technological Research and Development Centre (Shell) and TNO Prins Maurits Laboratory.

The outcome of the work was a valuable experimental database and improved understanding of explosion mechanisms and modelling accuracy—helping to improve assessments of vapour cloud explosion hazards.

Experimental setup

The experiments of MERGE involved a single array of pipes contained in a homogeneous gas cloud, enclosed in a polythene tent. The polythene tent contains the gas initially, however, does not act as confinement during the explosion. Therefore the experiments relate to congested and unconfined vapour cloud explosions.

The fuels involved in experiments included methane; propane; a mixture of methane and propane; and ethylene. The fuel concentration in the tests ranged between 4 and 10.2% volume in air. The experimental matrix showing all the simulations / tests performed is provided below.

Tests ID | Geo | Fuel | Concentration % (v/v) | ER [-] | DDT | Variables | |

|---|---|---|---|---|---|---|---|

Fuel | Oxygen | ||||||

A1 | A | Methane | 9.7 |

| 1.02 | No | P, FAT |

A2 | Propane | 4.1 | 1.02 | No | |||

A3 | Meth./Prop. | 5.5/1.8 | 1.05 | No | |||

A4 | Methane | 10.2 | 20.13 |

| No | ||

A5 | Meth./Prop. | 5.7/1.9 | 20.76 |

| No | ||

A6 | Propane | 4.4 | 20.51 |

| Yes | ||

A7 | Ethylene | 6.6 |

| 1.07 | Yes | ||

B1 | B | Methane | 9.8 | 1.03 | No | ||

B2 | Meth./Prop. | 5.5/1.8 | 1.05 | No | |||

B3 | Propane | 4.1 | 1.02 | No | |||

B4 | Ethylene | 6.7 | 1.026 | Yes | |||

C1 | C | Methane | 9.5 | 1 | No | P | |

C2 | Ethylene | 7 | 1.07 | No | |||

C3 | Propane | 4.3 | 1.07 | No | |||

C4 | Meth./Prop. | 5.6/1.8 | 1.05 | No | |||

D1 | D | Methane | 4 | 0.99 | No | ||

D2 | Methane | 10 | 1.05 | No | |||

D3 | Meth./Prop. | 5.5/1.8 | 1.05 | No | |||

D4 | Methane | 10.5 | 20.06 |

| No | ||

D5 | Meth./Prop. | 5.9/1.8 | 20.73 |

| No | ||

D6 | Propane | 4.4 | 21.47 |

| No | ||

D7 | Ethylene | 6.6 |

| 1.01 | Yes | ||

L1 | E | Methane | 10 | 1.05 | No | P, FAT | |

L2 | Propane | 4.1 | 1.02 | No | |||

L3 | Meth./Prop. | 5.5/1.87 | 1.05 | No | |||

L4 | CS | Methane | 9.7 | 1.02 | No | ||

L5 | Meth./Prop. | 5.4/1.9 | 1.05 | No | |||

L6 | Propane | 4.1 | 10.2 | No | |||

Obstacle setup

Multiple obstacle arrays were assessed in the experiments and referred to as types A, B, C, D, E, and CS. These are summarised in the table below. The geometries in FLACS are also shown in the figure below (for simplicity, only one of the B obstacle arrays is shown).

Obstacle array | Pipes diameter (mm) | Pipe pitch (m) | Volume blockage (%) | Rig dimensions (m) |

|---|---|---|---|---|

A | 43 | 0.2 | 10 | 4.5 x 4.5 x 2.25 |

B1 | 41 | 0.133 | 20 | 4.0 x 4.0 x 2.0 |

B2 | 41 | 0.133 | 20 | 4.0 x 4.0 x 2.0 |

B3 | 41 | 0.133 | 20 | 3.46 x 3.46 x 1.73 |

B4 | 41 | 0.133 | 20 | 3.2 x 3.2 x 1.33 |

C | 86 | 0.4 | 10 | 4.5 x 4.5 x 2.25 |

D | 82 | 0.267 | 20 | 4.5 x 4.5 x 2.25 |

E | 168 | 0.8 | 10 | 9.0 x 9.0 x 4.5 |

CS | 117 | 0.384 | 10 | 7.56 x 7.56 x 3.72 |

Obstacle Array A |

Obstacle Array B (B4 shown) |

Obstacle Array C |

Obstacle Array D |

|

|

Validating FLACS

FLACS is continuously validated against analytical solutions, experiments, and real incidents. The MERGE experiments were selected as one of the validation cases to assess the performance of GasEx in FLACS. This project was undertaken to address key issues relating to the influence on overpressure and flame acceleration from varying the volume blockage, pipe diameters, and fuels for particular obstacle configurations.

This article presents a worked example based on one of the tests from the experiments.

Geometry

The simulation geometry file is provided for obstacle array E (as per the table and figure in the previous section) and can be downloaded below. Once downloaded, open the geometry files in CASD. Now the geometrical model based upon the large scale test rig should be visible in CASD as in the image below.

Geometry steps

Within CASD navigate to File → Open → choose from the drop down Geometry files (co*.dat3;*.geo) → select and open co030162.geo.

.png)

Geometry shown in CASD based on the experimental setup of the MERGE experiments

Monitor points

Next, monitor points will be positioned throughout the geometry in order to represent the sensors which are used in the experiments. Add the following monitor points at the given locations.

Monitor point | X | Y | Z |

P1 | 0.05 | 0 | 0.01 |

P2 | 0.8 | 0 | 0.01 |

P3 | 1.6 | 0 | 0.01 |

P4 | 2.4 | 0 | 0.01 |

P5 | 3.2 | 0 | 0.01 |

P6 | 4 | 0 | 0.01 |

P7 | |||

P8 | 0 | 3.2 | 0.01 |

P9 | |||

P10 | 0 | 0 | 3.2 |

P11 | 8 | 0 | 0.01 |

P12 | 24 | 0 | 1 |

P13 | 48 | 0 | 1 |

P14 | |||

P15 | 4.4 | 0 | 0.01 |

P16 | 4.8 | 0 | 0.01 |

Next, choose the following variables monitored during the simulations:

Pressure

MassFractionProducts (combustion products mass fraction)

Temperature

PressureImpulse

PressureMax

PressureGradientNormalized

Results obtained for these monitor points will be used to analyse the explosion and compare against results produced by the sensors within the experiments.

.png)

Monitor points shown in FLACS defined at locations based on the sensors in the MERGE experiments

Monitor points steps

Monitor points can be defined by selecting Add then Edit before inputting the coordinates into Position.

Select all the monitor points (Ctrl + A whilst in the monitor point tab), edit and select the following variables:

Pressure

MassFractionProducts (combustion products mass fraction)

Temperature

PressureImpulse

PressureMax

PressureGradientNormalized

Single field 3D output

Next, the following 3D output variables should be selected from the list:

Pressure

MassFractionProducts

Temperature

VelocityVector

PressureMax

PressureGradientNormalized

PressureGradientNormalized_Max

Selecting these variables enables the user to visualise, analyse and export 3D plots of the results in Flowvis.

Simulation and output control

Within the simulation and output control tab enter following parameters, all other fields can be left as default values:

Timestep code = KEEP_LOW

NPLOT = 20

NPLOT is changed from the default output frequency (5) to allow smoother video output from Flowvis. However, this is optional and can be left as default. The minimum time and timestep codes are set because far field pressure is of interest in this scenario.

Simulation and output control steps

Expand the simulation and output control tab. Within the tab right-click -> Show advanced and then edit the following parameters:

Timestep code = KEEP_LOW

NPLOT = 20

Boundary conditions

The Plane Wave boundary condition should be set for all boundaries apart from the ZLO boundary, which should be set to Euler.

.png)

Recommended boundary conditions shown in CASD

The MERGE experiments are considered to be unconfined but congested. For low confinement scenarios, it is recommended to use the PLANE WAVE boundary condition. However, it is important that there is sufficient distance between the total simulation boundary and the combustion region to avoid any unphysical boundary effects.

Initial conditions

The initial conditions are selected in order to represent the experimental conditions. Quiescent turbulence conditions should be set as below, with all other parameters kept as default:

Characteristic Velocity (m/s) = 0

RTI ( - ) = 0

TLS (m) = 0

Defining the fuel region and gas composition

This step involves defining a gas cloud where the position and dimensions are representative of the real clouds present in the experiments. For scenario L2, define the following gas cloud:

Position = (-4.5, -4.5, 0) m

Size = (9×9×4.5) m

Volume fraction: Propane = 1

Equivalence ratio = 1.05

.png)

Fuel region shown in CASD based on experimental gas cloud in scenario A1

Ignition

Next, an ignition location is defined in the centre of the array close to the ground. This is based upon the ignition point used in the experiments. Set the ignition location coordinates as:

Position (0.005, 0.005, 0.005)m

All other parameters can be left as default.

.png)

Ignition location in FLACS shown at the centre of the array close to the ground

Creating the simulation grid

The simulation grid must cover the gas cloud with sufficient fidelity as well as extending far enough to prevent excessive interaction with the boundary considering that the plane wave boundary condition is selected.

A suitable grid can be generated using the Auto Grid functionality. The Z minimum for the maximum extent should be set to 0 and the maximum aspect ratio in the fuel region set to 1. All other parameters can be left as default.

This creates a refined region around the defined gas cloud with a suitable cell size to properly capture the cloud as well as appropriate near field, far field and maximum extents. This should result in a grid of around 127,000 cells. The resulting grid is shown in the image below.

.png)

The simulation can now be saved in an appropriate location and subsequently, once the porosities have been calculated, it is ready to run.

Running the simulation

The simulation setup is now complete. The next step is to run the simulation in RunManager.

RunManager steps

Firstly, add the directory and navigate to the folder where the simulation is stored. The simulation can be run in parallel with multiple threads to speed up the run time. The number of threads can be selected via Parameters → check Parallel run and enter the number of threads. The number of threads to select depends on the user’s computing power (the user should check the number of available threads on their machine and select appropriately).

Next, check the box next to the simulation job number and on the right hand side select Simulate.

Analysing the results

Once the simulation has finished, the results can be visualised and analysed in Flowvis and ultimately exported to a suitable format.

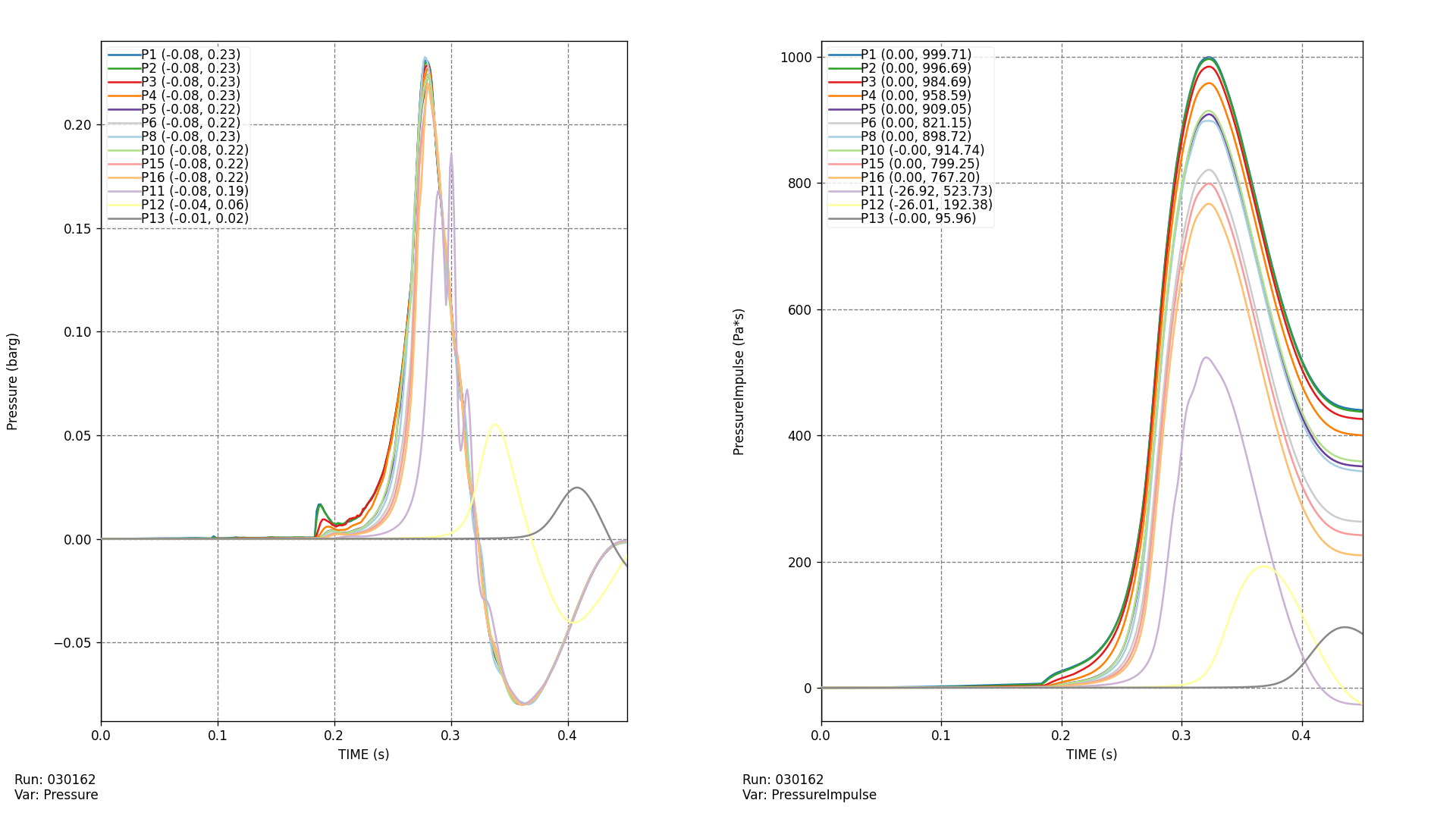

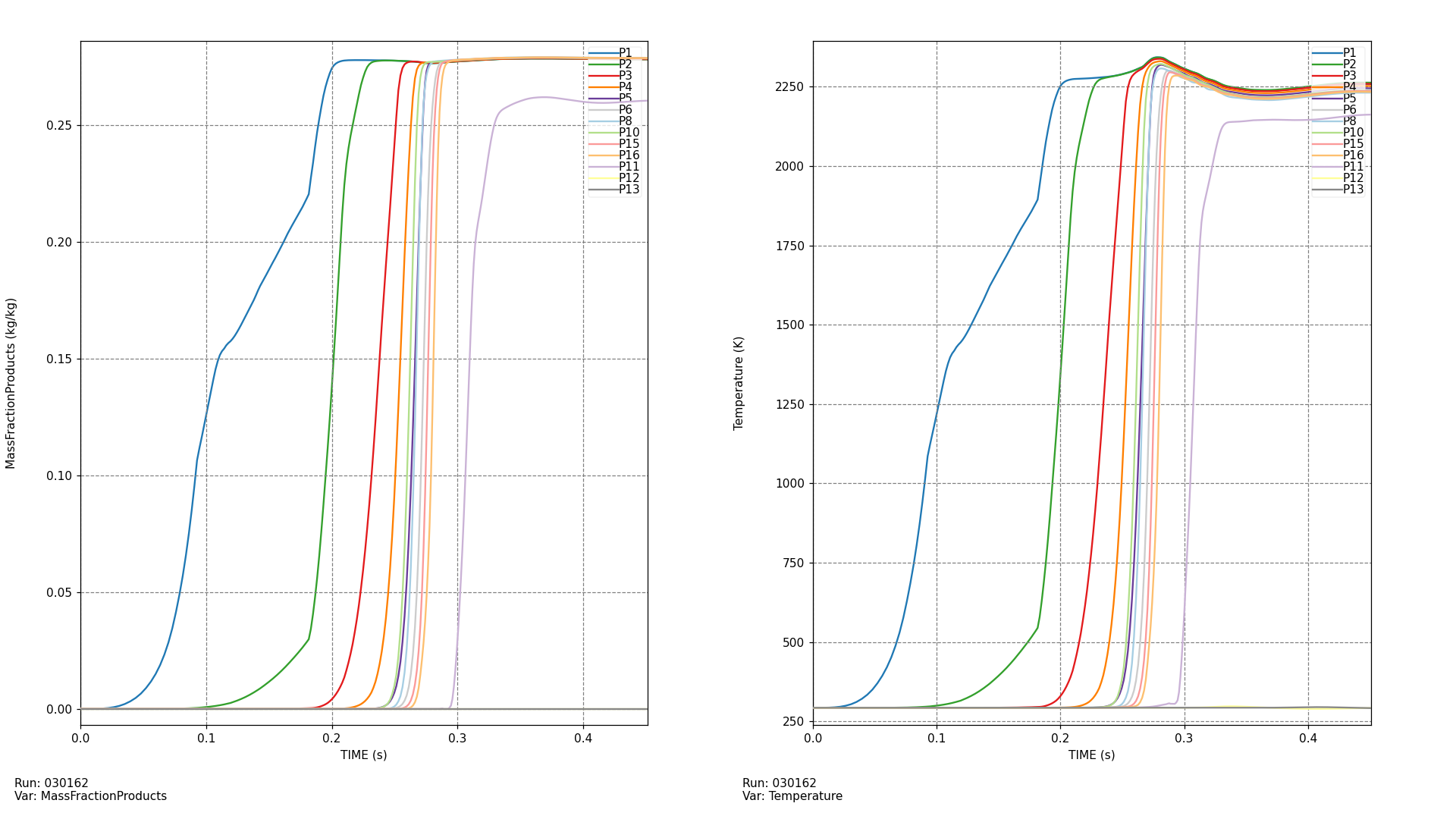

When validating against explosion experiments some of the key parameters to benchmark against are the pressure, pressure impulse and time of flame arrival; these parameters can be compared against the experimental data by creating pressure, pressure impulse and flame arrival time (FAT) plots respectively in Flowvis.

The maximum and minimum values of Scalar Time plots can be displayed by selecting Data Range in Legend (in the options tab or via right-click). This enables the user to quickly and easily determine the maximum pressure or pressure impulse values at monitor points, for example.

The exported results including the data range (contained within the brackets in the legend) are presented below.

Analysis steps

The results can be exported for the defined monitor points as follows:

Open Flowvis, select Scalar Time and add navigate to the relevant results file.

Select one of the desired variables (i.e., Pressure, PressureImpulse or MassFractionProducts) from the Variables list.

Select all monitor points and click OK.

These steps are shown in the video below.

Comparison against experimental results

Overpressures

The maximum overpressure results from the experimental data can be directly compared against the FLACS results. During validation efforts, the full pressure-time plots as well as the pressure impulse are compared however, this data cannot be shared publicly.

The table below shows a comparison of the FLACS maximum overpressures compared to the MERGE experimental results. The results show that FLACS predicts the maximum overpressure well. It should be noted that FLACS also performs very well against the pressure impulse. The overpressure results are also presented below in the form of a bar chart.

Maximum pressure (barg) | P1 | P2 | P3 | P4 | P5 | P6 | P8 | P10 | P11 | P12 | P13 | P15 | P16 |

MERGE | 0.232 | 0.234 | 0.230 | 0.233 | 0.215 | 0.224 | 0.218 | 0.192 | 0.281 | 0.052 | 0.029 | 0.215 | 0.221 |

FLACS | 0.231 | 0.230 | 0.229 | 0.227 | 0.224 | 0.219 | 0.232 | 0.224 | 0.186 | 0.055 | 0.025 | 0.219 | 0.220 |

.png)

Detonation prediction

FLACS-CFD is able to give an indication of the likelihood of deflagration to detonation transition (DDT). One of the criterion for DDT is the normalised pressure gradient (DPDX). This indicates whether the flame front reaches the pressure front. This parameter can be monitored throughout the simulation at monitor points or as a 3D variable. Generally, a DPDX value around 1 indicates that detonation is possible and a value above 2 indicates that detonation is likely.

In this example DPDX was monitored at the specified monitor points. The results are shown in the figure below and indicate that detonation does not occur (DPDX = 0 for all monitor points). This matches with the experiment where no detonation was observed for this scenario.

.png)

Time of flame arrival

Time of flame arrival is considered as the point in time when the flame front reaches a given location. This is another important validation parameter as it provides an insight into how well flame acceleration and flame front progression matches with experiments.

Flame progression can be assessed by analysing either temperature, combustion products or flame arrival time (FAT) results. In this example, FAT results have been exported and are shown in the figure below for all monitor points. A comparison of the monitor points vs the sensor locations in the experiment is provided in the table below.

N/A denotes a lack of data from the experiment and (-) denotes that flames do not reach the location.

Flame arrival (s) | P1 | P2 | P3 | P4 | P5 | P6 | P8 | P10 | P11 | P12 | P13 | P15 | P16 |

MERGE | 0.04 | 0.18 | 0.26 | 0.31 | 0.35 | 0.36 | 0.35 | 0.40 | N/A | N/A | N/A | 0.37 | 0.36 |

FLACS | 0.11 | 0.20 | 0.24 | 0.25 | 0.27 | 0.27 | 0.27 | 0.26 | 0.31 | (-) | (-) | 0.28 | 0.28 |

.png)

.png)

.png)

.png)

.png)

.png) Obstacle Array E

Obstacle Array E.png) Obstacle Array CS

Obstacle Array CS